Epping Pump Station

January 6, 2025

Completed December 2024

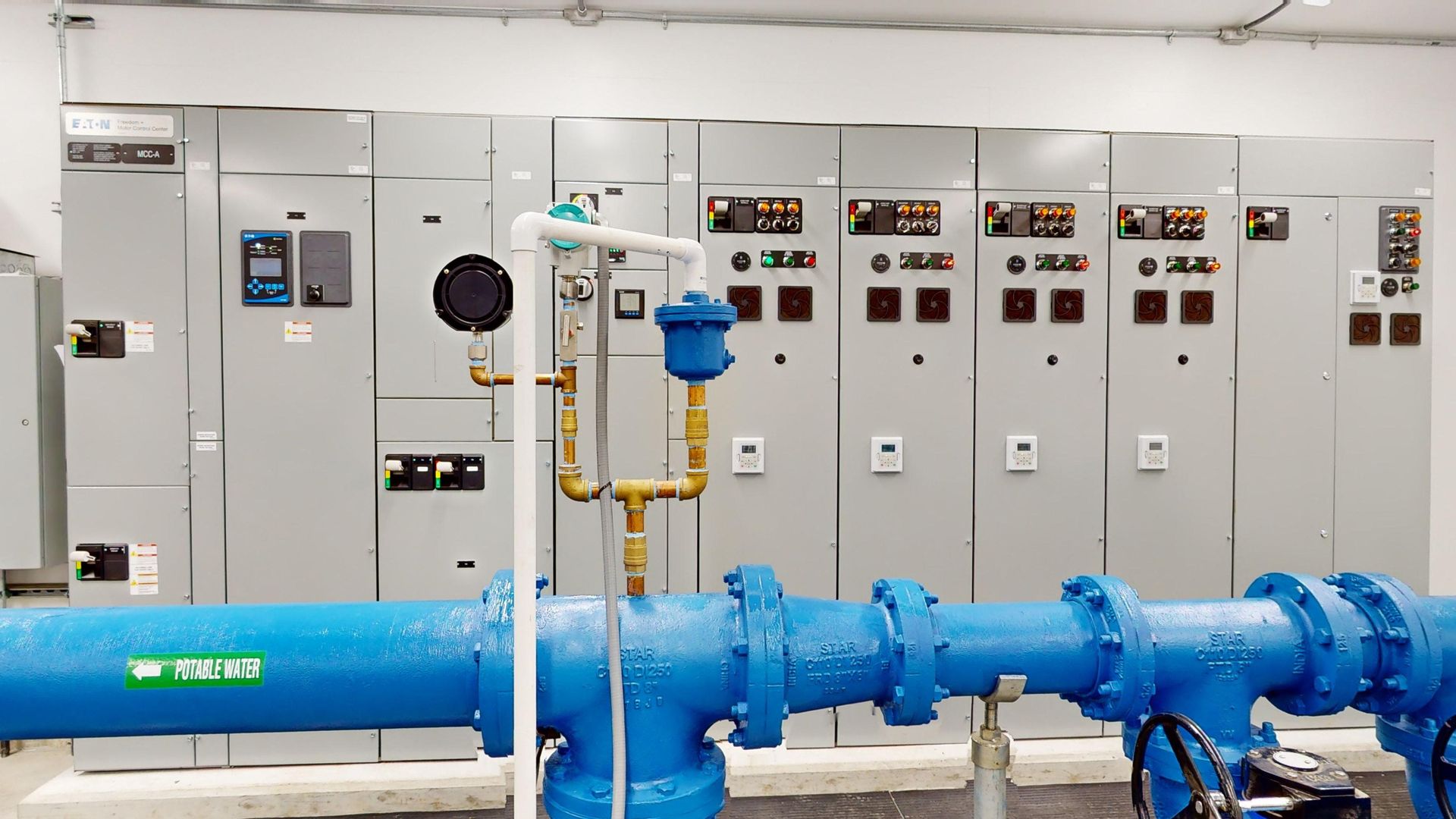

Water Booster Pump Station Project – Epping, NH

As part of the MtBE Water Main Extension Project, HAWSCO successfully constructed a 30’ x 20’ Water Booster Pump Station for the Town of Epping, NH, delivering the project from foundation to finish. The station features a wood-framed structure with durable vinyl shake siding, a wood truss system, and an asphalt shingle roof.

Interior Features and Mechanical Systems:

- Equipped with 12” Ductile Iron Water Mains for both inlet and outlet flows.

- Includes two Jockey Pumps, each with a capacity of 30 GPM.

- Two Booster Pumps, each rated at 200 GPM, to ensure efficient water distribution.

- A High-Demand Flushing Pump capable of delivering up to 960 GPM.

- All pumps are automatically controlled through Variable Frequency Drives (VFD) integrated with a SCADA system, allowing adjustable pressure and flow setpoints, alarm notifications, and programmed delays.

- Climate-controlled interior powered by a fully automated HVAC system.

Power and Backup Systems:

- Primary power is supplied through 480VAC Three-Phase service connected to custom switchgear with built-in surge protection.

- Backup power is provided by an Automatic Transfer Switch (ATS) and a 100KW propane generator, supported by three 1,000-gallon propane tanks for reliability during outages.

This state-of-the-art booster pump station enhances water supply efficiency and reliability for the Epping community, showcasing HAWSCO’s expertise in delivering high-quality water infrastructure projects.

The Bedford NH Pump Station is a Booster Station that provides Water for domestic use, irrigation and Fire Protection for a new development. HAWSCO performed all work from the Foundation up for a 22’ x 24’ CMU Building that is strapped and sided with Vinyl Siding, new 208 VAC Electric Service, a full HVAC System, REPCO Control System with full Instrumentation and Controls, and a 100 KW Natural Gas Generator.

The Newmarket NH Tucker Well Project consisted of HAWSCO providing and installing a 40 HP 40VAC Submersible Turbine Well Pump complete with Casing Extension, Pitless Adapter and all accessories, providing and installing 7200 Linear Feet of 10” HDPE Water Main with all Hydrants and Gate Valves as required, all required Site Work and restoration for the Water Main installation as well as Drainage and Access Road installation to and from the Well, installation of the Town’s repurposed Generator with LP Tank and accessories, New 480 VAC Electric Service and Poles from the Road to the Station, as well as the Pump Station Building that houses all of the Electrical, Controls and Instrumentation and HVAC Systems complete.

East Road Booster Pump Station HAWSCO is actively engaged with the Southern NH Regional Water Project (SNHRWP) and, as part of the overall project, completed the construction of this booster station in Plaistow, NH. The East Rd Booster station supplies water from the SNHRWP pipeline to the Town of Plaistow at a rate of up to 500 GPM filling the newly constructed 400,000 Gallon Water Tank on Sweet Hill Rd. HAWSCO constructed the Booster Station facility complete from the ground up including but not limited to site work, building construction, installation of the 2 Booster Pumps, all related piping, valves, instrumentation, sampling equipment and electrical control panels for the Town of Plaistow. There are two 20 HP Domestic Water Pumps that deliver 500 GPM each at 95’ TDH through 12” Ductile Iron Mains. This station is designed to automatically maintain programmed level setpoints in the Sweet Hill Water Tank with variable flows of 0-500 GPM through VFD’S and a SCADA Control System with a local SCADA control panel with a Touchscreen Operator Interface and remote SCADA PC’s with a fully programmable control system and alarm call out system.