Rockingham County Complex Greensand Filtration System Design/Build

Completed July 2025

Rockingham County Complex – Brentwood, NH

Greensand Filtration System Design/Build

HAWSCO was contracted by the Rockingham County Complex in Brentwood, NH to complete a full design/build upgrade of its Greensand Filtration System. The water system serves a large and diverse group of buildings including general administrative offices, a nursing home, an assisted living facility, a correctional facility, engineering and maintenance buildings, and the offices of various elected officials. The project also included integrating service to the newly constructed Sheriff’s Building.

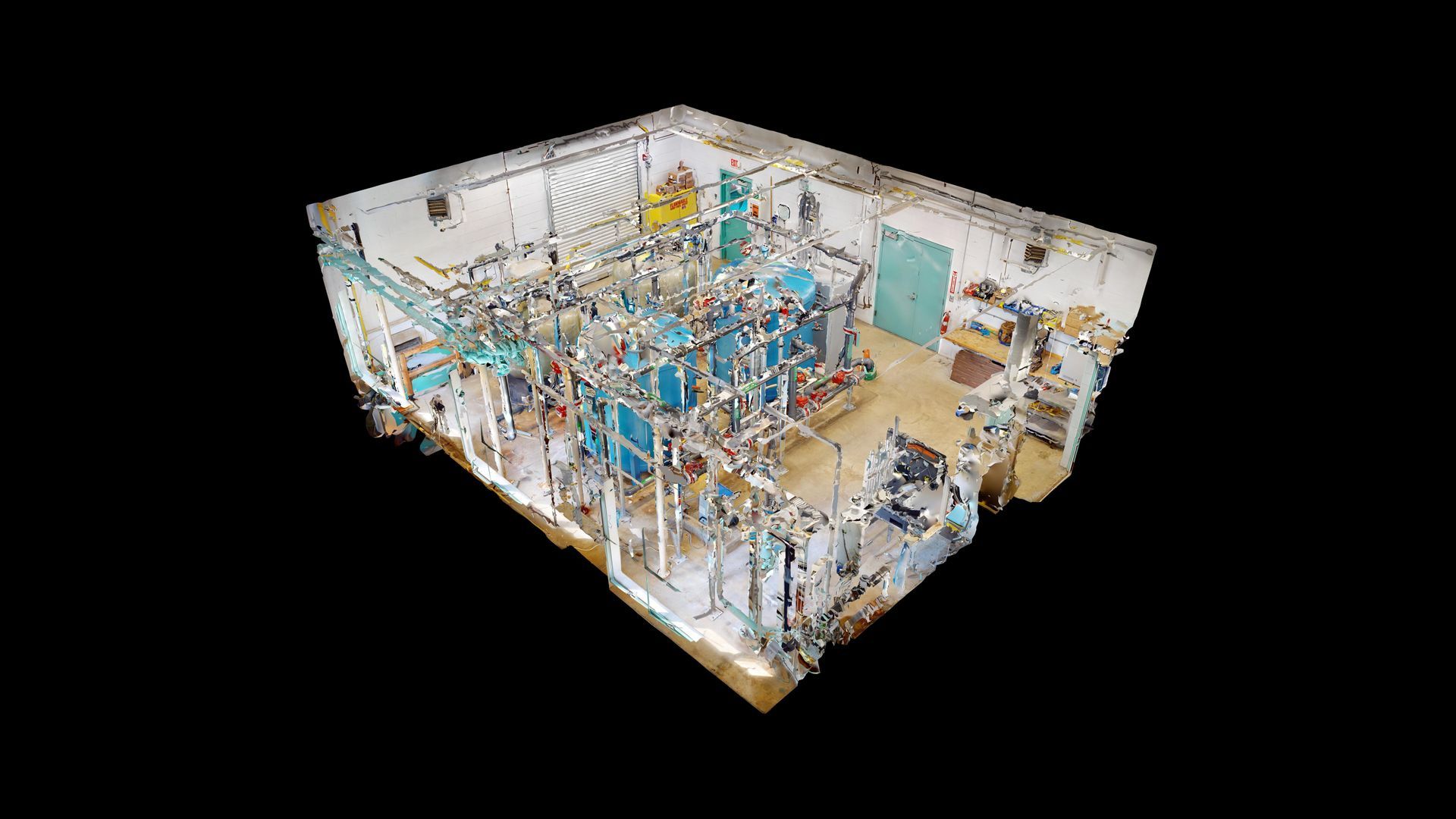

To maintain uninterrupted operation during construction, HAWSCO first installed a temporary filtration system. The existing filtration system—consisting of two 8-foot diameter greensand filter vessels, associated valves, controllers, and piping—was fully removed.

HAWSCO then furnished and installed two new 8-foot diameter pressure filter vessels, each capable of handling 120 GPM. Each vessel was equipped with inlet distributors, backwash collectors, air wash and underdrain distribution systems, and new media including gravel, anthracite, and greensand. All new Schedule 80 PVC piping was installed with resilient-seated butterfly valves and electric actuators for full control integration. A high-capacity blower and stainless steel air scour piping were installed to improve backwashing efficiency.

Instrumentation and control upgrades included new magnetic flowmeters, pressure transducers, and other control devices, all integrated with the main control panel. The project also replaced and upgraded all chemical feed systems, including new peristaltic pump skids with calibration columns, day tanks, injection quills, and safety accessories for both KMnO₄ and sodium hypochlorite.

The system’s SCADA platform was upgraded to allow for full automation and communication between the filtration system and central plant control. Filters now regenerate based on differential pressure or flow totalization, whichever occurs first. Since commissioning, the upgraded system has quadrupled filter runtime between regenerations while using only one-third of the water previously required—resulting in significant water and energy savings.